-

Material Technologies

Make the impossible possible.

Our aim is to bring you a hearty smile and abundance of life.

Our Company

-

About us

We are a "group thinking of technology" looking ahead to the future, and always take on new research development. Technical employees, who make up about one third of all our employees, work in research and technology development.

-

Corporate Social Responsibility Policies

Value the obvious.

We make our company a safe, healthy, and hopeful place to work for our customers, community, employees and their families. -

Logo Story

Reshape common sense. We develop new materials that are world firsts, and contributing to the world. And furthermore to the universe. We hope that the materials we generate will be given life and utilized to lead to significant world improvement.

-

Business locations and transportation access

I.S.T's own technology has increased its need on a global scale, and we’ve expanded our activity locations. The network that connects research development, production, and sales at each location responds rapidly to the accelerating change of the times.

-

Careers

We are a group that is always thinking and constantly trying out new things. After each of us aggressively puts ideas out, we give a concrete shape to them, and manufacture things to be of advantage to companies and the world.

-

Sales agency SAKANE SANGYO Co., Ltd.

As a general sales agency of I.S.T Corporation, we sell various functional products, such as heat-resistant polyimid resin, office automation equipment parts, FRP parts, nonflammable function textile products, and clothing textile products.

Business Outline

-

Pyre-M.L.

Varnish is used to form a polyimide membrane with heat and voltage resistance, as well as having high-level mechanical strength. This material is used in a wide range of fields, such as electric wire coating materials for airplanes, as well as for medical tubes, due to its excellent features.

-

SKYBOND

Polyimide varnish is used for heat-resistant and high strength compound materials, with many actual usages being achieved in airplanes. This material has the most thermal stability and adhesive properties among currently commercialized and mass-produced high-polymer materials.

-

SKYBOND 8000

High heat-resistant polyimide resin is based on I.S.T's proprietary techniques, which are used to form RTM (Resin Transfer Molding). Polyimide carbon FRP with very few voids can be made through injection forming.

-

SKYBOND FOAM

A compact light-weighted polyimide foam with heat resistance and a low dielectric constant. The foam density can be controlled, and a wide range of foams from a 100 micrometer-thick thin film (sheet) to thick film (block) can be manufactured.

-

High thermal conductive Polyimide Composite

High heat-resistant polyimide composite with excellent thermal conductivity. This composite, which is lighter than metals, has the combined properties of a high glass-transition temperature derived from polyimide resin, and an extremely low CTE and high thermal conductivity derived from carbon fabric.

-

DREAMBOND

Binder for lithium-ion battery silicon anodes. This material has excellent adherence properties for copper foil and silicon alloy, and 97% of battery capacity can be retained after 400 cycles of charging and discharging.

-

Polyimide tube/belt

Heat-resistant and high strength seamless tube. This material is widely used in Japan and abroad for such applications as office automation equipment (copiers, printers), transfer/drive mechanisms of precision equipment, laminated belts in the high temperature range, and insulating sleeves.

-

IMIDETEX

A polyimide super fiber, IMIDETEX®, offers 3.0 GPa strength, 250℃+ continuous use, and ultra-low water absorption (<0.9%). Combining it with other materials unlocks new properties.

-

TORMED

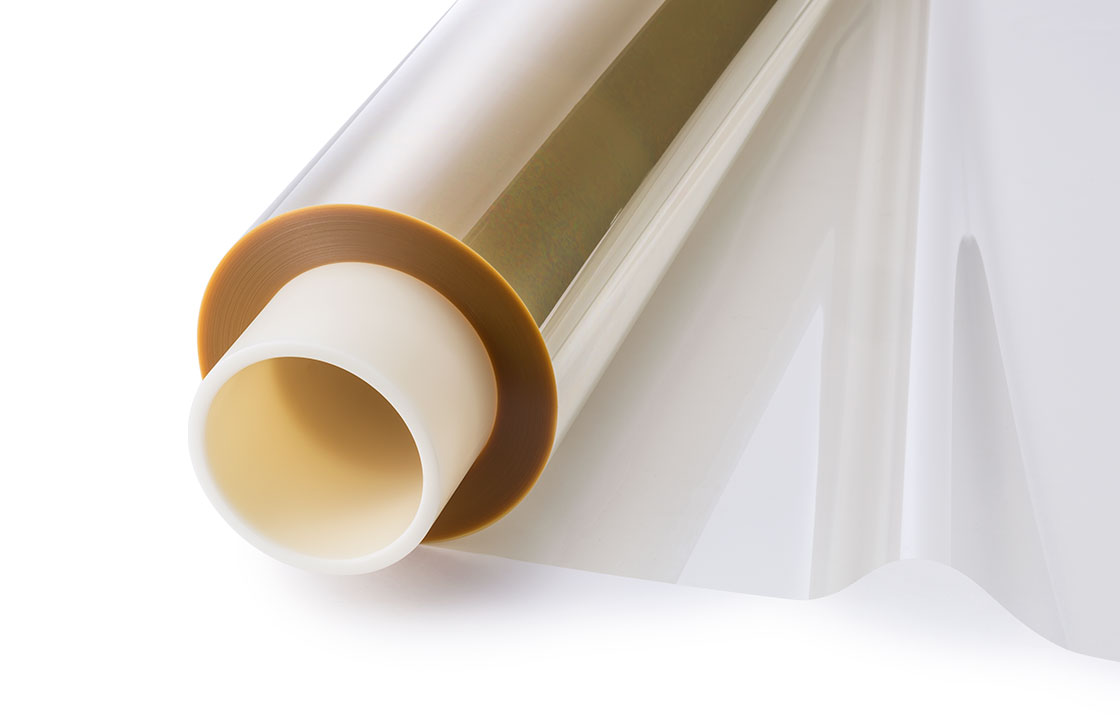

Transparent polyimide film with high heat resistance of 300ºC (570℉) and visible light transmission of 90% or more. We have also developed in-house equipment that is used to form film into a continuous roll, and have prepared the production system.

-

TORMED possible applications : Flexible LED Displays

Because of the features of TORMED high clarity and high heat resistance, LED displays made with TORMED can be brighter, more durable, and more flexible than ordinal displays.

-

TORMED Possible Applications : Flexible Printed Circuit Boards

Transparent flexible printed circuit boards have many possibilities for future development. As they can be wired without obstructing the view, they allow for greater freedom in mobility device design.

-

TORMED Possible Applications : Flexible Solar Panels

Flexible solar panels can be placed anywhere, and this allows drastically increasing the number of installations of eco-friendly systems. Make this happen with TORMED.

-

ISTFLON

YarnNonflammable, high strength sewing yarn. This is nonflammable sewing yarn with excellent flex resistance, sliding characteristics, and chemical resistance.

-

ISTFLON

Nonflammable ClothThis nonflammable fabric material is woven with nonflammable, rich-textured color yarn developed using our proprietary composite technology. This is nonflammable wall covering cloth that has both a soft texture and high construction durability, in addition to a premium feel that has never been seen in conventional nonflammable cloth.

-

ISTFLON

Sound Absorption BoardGlass wool sound absorption board with unprecedented texture of woven fabric and a new design. The concavo-convex or frame processing is applied to the joint parts, which results in well-fitted joints, and construction with an excellent finishing.

-

ISTFLON

Sound Absorption Wall SystemA sound absorption interior wall system excellent in design.Original sound absorption walls can be created.

-

ISTFLON

Sound Absorption PanelMagnet-type sound absorption panels. These panels can be quickly attached to or removed from surfaces such as steel partitions, where magnets can be used. Depending on the number of panels to be installed, the acoustic effects can be easily adjusted.

-

ISTFLON

Nonflammable Wall PaperNonflammable wall paper with both a soft texture and a premium feel, developed using our proprietary composite technology. This wall paper can be safely used in places that require nonflammable finishing, such as hotels, stores, commercial facilities, and medical and welfare facilities.

-

IST PLATINUMWOOL™

IST PLATINUMWOOL™ redefines what you can expect from natural fibers. Thanks to IST’s exclusive patented technology, it’s as soft as a newborn baby’s skin but surprisingly cool to the touch. With its elegant charm and a hint of mystique, PLATINUMWOOL™ adds a touch of splendor to your luxurious lifestyle.

-

KARL KARL

YarnKARL KARL YARN is a new airy and light yarn that maintains a soft texture, which enables the production of clothes to have a very soft and sponge-like elastic characteristic.

-

CARMEN

Lightweight cotton yarn with excellent water-absorption and quick-drying properties. With the special two-layer structure, it maintains a light and soft texture, and hardly generates lint.

-

Kit Fit

"Super aesthetic" next-generation wool stretchable yarn. Using yarn that produce a shiny and elegant gloss has made this high-class material a reality, in spite of it being a stretchable material.

-

Night Light

A more delicate, and beautiful super fine wool yarn. The two-folded yarn 2/200 produces extremely fine textured, beautiful, thin, and soft wool textile, just like a robe of feathers.

-

alatona

Thin and light air-in fabric that allows ventilation. This yarn is woven by hollow wool fibers that include more air layers inside, and characterized by being very light and warm, as well as having high ventilation.

-

R&D

Material/Special Parts/EquipmentWe develop new materials under our motto of developing things that are world firsts. We continue to utilize next-generation themes through joint research with universities and institutions in Japan and abroad, as well as our own development of independent equipment.

-

Production Equipments

All our trial equipment and production facilities have been designed and manufactured by ourselves, since the foundation of the company. We can also accept consultations and provide our knowledge, regarding production equipments when cannot be made using general equipment manufacturers.

-

IT SYSTEM

We build and sell the most appropriate system on a custom-made bases for manufacturing companies that need solutions to several problems, for example, when commercially available package software does not fit in with their business contents.

-

Proactive employment of the elderly

In our I.S.T Kami factory, a major production base in Hyogo Prefecture, we have improved various production jobs through production reformation into simplified jobs anyone can do, giving new employment opportunities to the elderly in the communities.

-

Nursing-care support activities

We have implemented our own CSR activities since January, 2013. Based on these activities, we help our employees obtain nursing care qualifications at the company's expense, and send them to nursing-care facilities while maintaining their contracted compensation packages.

-

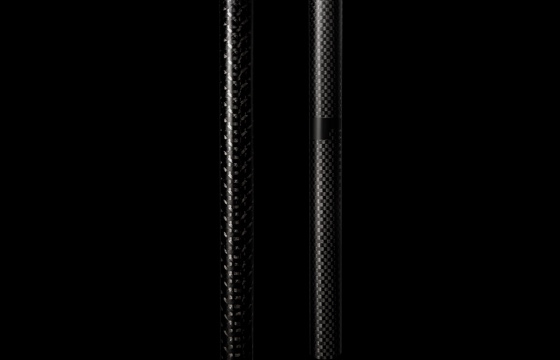

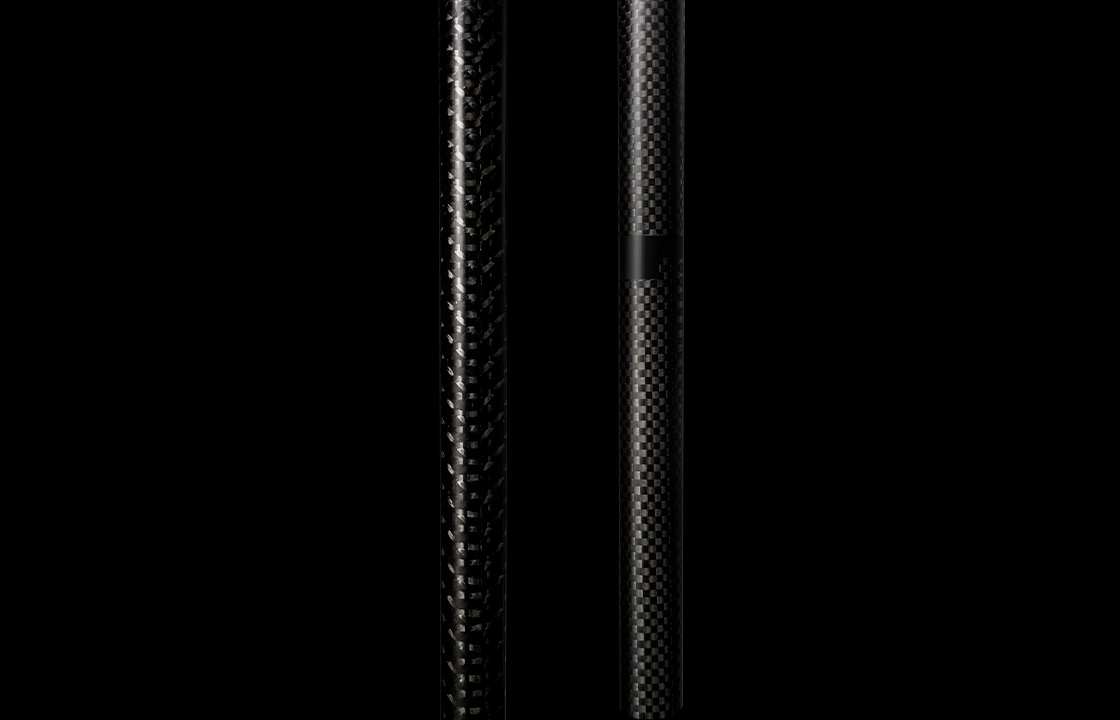

IMIDE AND SUNS

Golf ShaftThe technology of seven dreamers and the technology of I.S.T are gathered and a new brand began.

-

Fashion

Custom-madeIn order to achieve both reasonable prices and high quality, we mainly use our own company’s materials, and have our artisans involved in making patterns from direct measurement and manual cutting. Please experience an "affordable and genuine satisfaction" that cannot be gained with pattern-ordered products.